Diaphragms ITT Style

Diaphragm Direct® replacement diaphragms (ITT Style)

Kenmerken

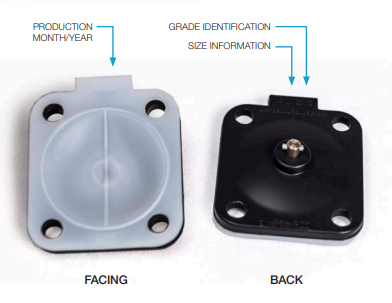

- Full traceability

- Molded identification number

- Innovative formulations

- Durability

Diaphragm Direct® range of diaphragms has been designed to meet the highest standards of reliability and quality. Full traceability is available on all Diaphragm Direct® replacement diaphragms. Each diaphragm carries a molded identification number and is available with a certificate of FDA and USP conformity for your regulatory requirements.

Diaphragm Direct® replacement diaphragms have been designed specifically to improve performance in applications requiring frequent steam cycles. Innovative formulations in EPDM and PTFE technology mean that Diaphragm Direct® replacement diaphragms can stay in service significantly longer than conventional diaphragms.

To Download Diaphragm Drawings please check bellow table

| Size | Material | OEM CODE | Drawing |

| 1/4" | EPDM | DD03-IE7 | DD03-IE7 |

| 1/4" | PTFE/EPDM 2LAYERS | DD03-ITFM | DD03-ITFM |

| 1/2" | EPDM | DD05-IE7 | DD05-IE7 |

| 1/2" | PTFE/EPDM 2LAYERS | DD05-ITFM | DD05-ITFM |

| 3/4" | EPDM | DD07-IE7 | DD07-IE7 |

| 3/4" | PTFE/EPDM 2LAYERS | DD07-ITFM | DD07-ITFM |

| 1" | EPDM | DD10-IE7 | DD10-IE7 |

| 1" | PTFE/EPDM 2LAYERS | DD10-ITFM | DD10-ITFM |

| 1.1/2" | EPDM | DD15-IE7 | DD15-IE7 |

| 1.1/2" | PTFE/EPDM 2LAYERS | DD15-ITFM | DD15-ITFM |

| 2" | EPDM | DD20-IE7 | DD20-IE7 |

| 2" | PTFE/EPDM 2LAYERS | DD20-ITFM | DD20-ITFM |

| 2.5" | EPDM | DD25-IE7 | DD25-IE7 |

| 2.5" | PTFE/EPDM 2LAYERS | DD25-ITFM | DD25-ITFM |

| 3" | EPDM | DD30-IE7 | DD30-IE7 |

| 3" | PTFE/EPDM 2LAYERS | DD30-ITFM | DD30-ITFM |

| 4" | EPDM | DD40-IE7 | DD40-IE7 |

| 4" | PTFE/EPDM 2LAYERS | DD40-ITFM | DD40-ITFM |

| 6" | EPDM | DD60-IE7 | DD60-IE7 |

| 6" | EPDM | DD60-ITFM | DD60-ITFM |

Brand: DIAPHRAGM DIRECT / ITT STYLE

PRODUCT VARIATIONS

This product has multiple variations to fit project-specific needs. Add the desired variant

to a free, no-obligation quote, and our sales team will review it for accurate pricing.

if your product is not in the list, please send us your needed product in mail

| SKUoooo | Type Execution | Size | Material | OEM | OEM Code 1 | OEM Code 2 | Quantitiiiiiiiiiiii | Add to Quote |

|---|---|---|---|---|---|---|---|---|

| SKUoooo: MIX-03-C-E-T-- | Type Execution: Normally Close | Size: 1/4 | Material: EPDM | OEM: DD03-IE7 | OEM Code 1: 41502 | OEM Code 2: 46602 |

|

|

| SKUoooo: MIX-03-C-Q-T-- | Type Execution: Normally Close | Size: 1/4 | Material: PTFE/EPDM 2LAYERS | OEM: DD03-ITFM | OEM Code 1: 42175 | OEM Code 2: 48069 |

|

|

| SKUoooo: MIX-05-O-E-T-- | Type Execution: Normally Open | Size: 1/2 | Material: EPDM | OEM: DD05-IE7 | OEM Code 1: 41281 | OEM Code 2: 46603 |

|

|

| SKUoooo: MIX-05-C-Q-T-- | Type Execution: Normally Close | Size: 1/2 | Material: PTFE/EPDM 2LAYERS | OEM: DD05-ITFM | OEM Code 1: 42176 | OEM Code 2: 48071 |

|

|

| SKUoooo: MIX-07-O-E-T-- | Type Execution: Normally Open | Size: 3/4 | Material: EPDM | OEM: DD07-IE7 | OEM Code 1: 41282 | OEM Code 2: 46604 |

|

|

| SKUoooo: MIX-07-C-Q-T-- | Type Execution: Normally Close | Size: 3/4 | Material: PTFE/EPDM 2LAYERS | OEM: DD07-ITFM | OEM Code 1: 42177 | OEM Code 2: 48072 |

|

|

| SKUoooo: MIX-10-C-E-T-- | Type Execution: Normally Close | Size: 1 | Material: EPDM | OEM: DD10-IE7 | OEM Code 1: 41283 | OEM Code 2: 46605 |

|

|

| SKUoooo: MIX-10-C-Q-T-- | Type Execution: Normally Close | Size: 1 | Material: PTFE/EPDM 2LAYERS | OEM: DD10-ITFM | OEM Code 1: 42178 | OEM Code 2: 48073 |

|

|

| SKUoooo: MIX-15-C-E-T-- | Type Execution: Normally Close | Size: 1.1/2 | Material: EPDM | OEM: DD15-IE7 | OEM Code 1: 41284 | OEM Code 2: 46606 |

|

|

| SKUoooo: MIX-15-C-Q-T-- | Type Execution: Normally Close | Size: 1.1/2 | Material: PTFE/EPDM 2LAYERS | OEM: DD15-ITFM | OEM Code 1: 42179 | OEM Code 2: 48074 |

|

|

| SKUoooo: MIX-20-C-E-T-- | Type Execution: Normally Close | Size: 2 | Material: EPDM | OEM: DD20-IE7 | OEM Code 1: 41285 | OEM Code 2: 46607 |

|

|

| SKUoooo: MIX-20-C-Q-T-- | Type Execution: Normally Close | Size: 2 | Material: PTFE/EPDM 2LAYERS | OEM: DD20-ITFM | OEM Code 1: 42180 | OEM Code 2: 48075 |

|

|

| SKUoooo: MIX-25-C-E-T-- | Type Execution: Normally Close | Size: 2.1/2 | Material: EPDM | OEM: DD25-IE7 | OEM Code 1: 41286 | OEM Code 2: 47002 |

|

|

| SKUoooo: MIX-25-C-Q-T-- | Type Execution: Normally Close | Size: 2.1/2 | Material: PTFE/EPDM 2LAYERS | OEM: DD25-ITFM | OEM Code 1: 42182 | OEM Code 2: 48077 |

|

|

| SKUoooo: MIX-30-C-E-T-- | Type Execution: Normally Close | Size: 3 | Material: EPDM | OEM: DD30-IE7 | OEM Code 1: 41286 | OEM Code 2: 47002 |

|

|

| SKUoooo: MIX-30-C-Q-T-- | Type Execution: Normally Close | Size: 3 | Material: PTFE/EPDM 2LAYERS | OEM: DD30-ITFM | OEM Code 1: 42182 | OEM Code 2: 48077 |

|

|

| SKUoooo: MIX-40-C-E-T-- | Type Execution: Normally Close | Size: 4 | Material: EPDM | OEM: DD40-IE7 | OEM Code 1: 41287 | OEM Code 2: 47003 |

|

|

| SKUoooo: MIX-40-C-Q-T-- | Type Execution: Normally Close | Size: 4 | Material: PTFE/EPDM 2LAYERS | OEM: DD40-ITFM | OEM Code 1: 42183 | OEM Code 2: 48078 |

|

|

| SKUoooo: MIX-60-C-E-T-- | Type Execution: Normally Close | Size: 6 | Material: EPDM | OEM: DD60-IE7 | OEM Code 1: 43270 | OEM Code 2: ---- |

|

|

| SKUoooo: MIX-60-C-Q-T-- | Type Execution: Normally Close | Size: 6 | Material: PTFE/EPDM 2LAYERS | OEM: DD60-ITFM | OEM Code 1: 42184 | OEM Code 2: 48079 |

|

|

| Sizes | 1/4″ – 6” |

| Temp. range | -30°C to 150°C Max Steam Sterilization (max 180 minutes per cycle) |

| Connections | Threaded Pin |

| Material | EPDM EPDM /PTFE |

| Traceability | Full batch traceable according to EN10204 3.1b, and ISO 10993-1 |

| Certificates | FDA , USP Class VI,

ISO 10993-5,6,-10,-11; 3A; ASME BPE (SG-3.1; SG-3.4); EMEA/410/01-TSE/BSE |

BROCHURES

No brochures are available at the moment.

There is no video for this product yet, check back later.

We utilize cookies to ensure you have the best possible experience while visiting our website.

We utilize cookies to ensure you have the best possible experience while visiting our website.