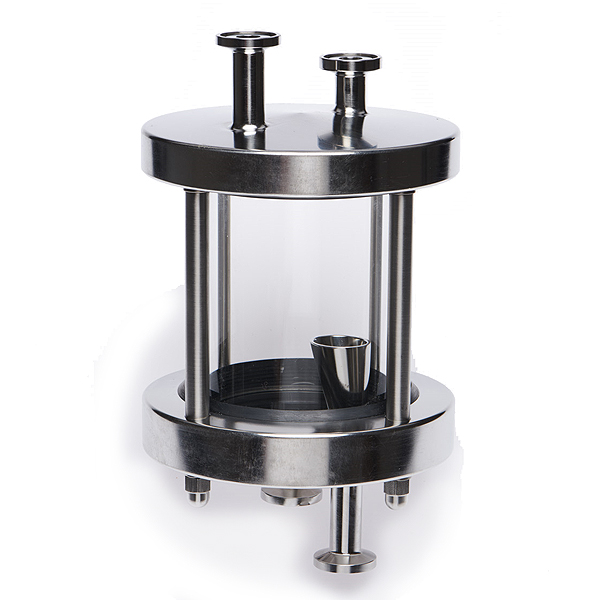

Bubble trap

Pharmaceutical Bubble Trap

Kenmerken

- Crevice Free design

- Eliminates bacteria

- Collection areas

- Viewing cylinder

- Allows the user to visibly see the level of the media inside the bubble trap

Bubble traps are used to detect and remove process gases in pharmaceutical and process applications.

Bubbles or gases can cause several errors in a process. Bubble traps make sure that unwanted process gases are detected and removed. They have been carefully developed with a minimum amount of crevices to help prevent the build-up of bacteria.

All threads are self-enclosed for easy wipe down, whilst shouldered tie rods ensure correct O-ring compression, making reassembly and maintenance simple. In addition, when installed in an upright position, the angled surfaces of our bubble trap encourage self-draining, making it easier to wash down the unit and ensure hygiene standards are maintained.

OPTIONS

- Alternative materials: Body: C22, Glass: Acrylic (USP Class VI)

Kindly notice that those products are engineered and produced following client requests. Each product needs to be calibrated for special properties such as size or connection. In order to make it possible, our sales team will assist you to determine those criteria together. Only when this process is finished ROMYNOX will we be able to produce a quote and share a price.

If you need to get in touch with our engineers, please visit our "Contact Us" page and fill out the form.

Our team will respond to your inquiry as soon as possible.

Brand: ROMYNOX

Overview

This product features a custom configuration designed to meet your specific needs. Our sales team will review the options with your after receiving your quoute request, ensuring the best solution for your requirements.

| Sizes | 3" to 10" (for inlet and outlet sizes see datasheet) |

| Max. pressure | up to 7 bar (depending on size) |

| Temp. range | -50°C to 150°C |

| Connections | Tri-Clamp |

| Material | - Body: 1.4404 (316L) - Glass: 3.3 Borosilicate - O-ring: EPDM |

| Surface finish | Interior surfaces SF4 (for Base and Lid) |

| Certificates (standard) | 3.1 material, FDA, USP Class |

| Certificates (optional) | 2.2 surface finish |

BROCHURES

Download the brochure for a quick overview of the product's features,

benefits, and applications.

There is no video for this product yet, check back later.

We utilize cookies to ensure you have the best possible experience while visiting our website.

We utilize cookies to ensure you have the best possible experience while visiting our website.