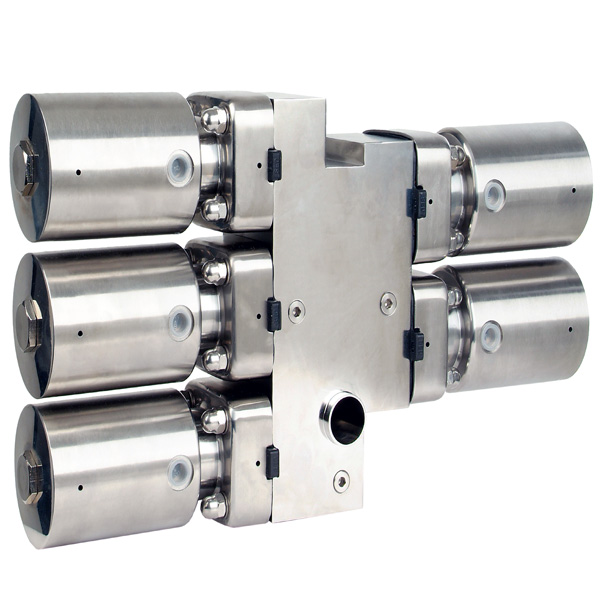

SED - Multi block Diaphragm valve

Compact multiblock with stainless steel diaphragm valves and stainless steel or plastic actuators

Kenmerken

- compact

- one block of stainless steel

- minimal surface contact

- faster and easier cleaning (SIP-CIP)

Romynox delivers SED multi block diaphragm valves for high purity applications in the pharmaceutical, food, fine chemical and cosmetic industries. The SED multi block diaphragm valves includes the same features and performance of a standard 2-way diaphragm valve of the KMA and Steripur series.

By using SED multiblock the diaphragm valves design process circuits can be assembled from one block of stainless steel. Due to a minimal of contact makes the system faster. And cleaning is easier (CIP –SIP). With this design seal mass will be removed as much as possible. This will increase the heat absorption and the valve assembly quickly sterile (SIP).

The multiport valves can be made in many different variations according to the wishes. For various examples see datasheet at the bottom of this page.

Options:

- Handle: control valve or open-close signaling

- Other materials: 904, Hastelloy

- Special versions: Customization is always possible

Brand: SED

Overview

This product features a custom configuration designed to meet your specific needs. Our sales team will review the options with your after receiving your quoute request, ensuring the best solution for your requirements.

| Sizes | Bore: DN 4 to DN 10 |

| Material | Body: 316L , (forged) Diaphragms: EPDM, PTFE, silicone Actuators: stainless steel or plastic |

| max temp | 150°C |

| max. presure | 10 bar |

| Connections | – Orbital welding connection with standards; ISO, ASME , DIN and SMS – Tri-clamp connection with standards; ASME BPE, DIN 32676 , DIN 11861 |

| Finish: | – surface finish Ra value to max 0.25 um – electro- polished or only mechanically polished – or ASME BPE 2012 Table SF5 |

| Operation | manual and actuator (pneumatic) |

| Certificates | 3.1, FDA , USP Class VI , CE / PED |

| Certificates (optional) | surface finish certificate, ATEX |

DATASHEETS

Download the datasheets to find all the technical information you need for

this product, including specifications and performance details.

BROCHURES

No brochures are available at the moment.

There is no video for this product yet, check back later.

We utilize cookies to ensure you have the best possible experience while visiting our website.

We utilize cookies to ensure you have the best possible experience while visiting our website.